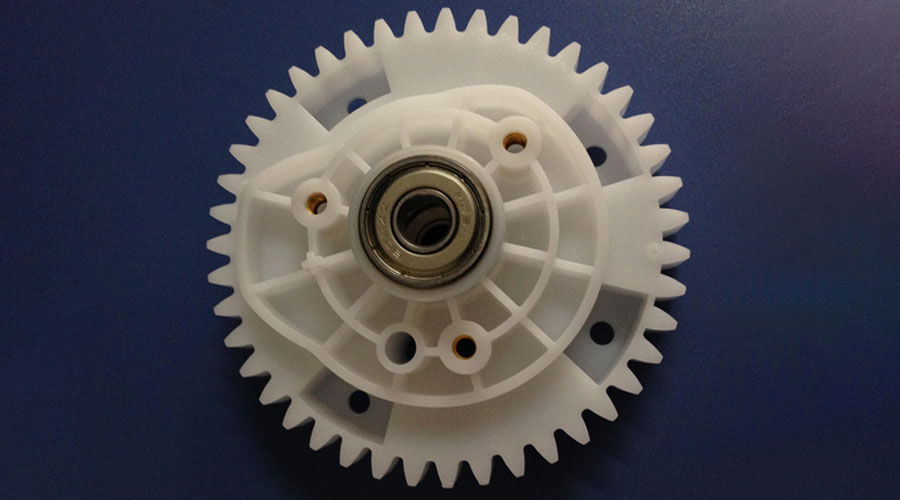

Fast Prototype Example: 3D Printed PTJ Engineering Plastic Wear-resistant Gears

Table of Contents

| Yinlong quickly manufactures customized high-wear-resistant gears through PTJ Shop’s 3D printing service |

Increasing prototype production time and costs may expose startups to insufficient funding. Therefore, Yinlong, a high-tech company based in Zhuhai, Guangdong, chose to use igus’ 3D printing service. This service configures parts such as gears online, then prints them cost-effectively using abrasion-resistant, high-performance engineering plastics, and can be delivered in a short period of time.

One of the reasons why the market demand for electric vehicles has not skyrocketed is that its charging infrastructure is still in its infancy. For many drivers, very few charging facilities are available. Yinlong hopes to change this situation. As an innovative start-up, Yinlong has developed a Dongcheng electric vehicle charging system consisting of a charging connector and a charging board. The charging board connected to the power supply is installed in the parking lot. When the electric vehicle is parked above the charging pad, the charging connector on the bottom of the vehicle is lowered and attached to the charging pad. The charging process is automatic, and the driver does not need to manually connect the cable-similar to inductive charging, but the charging power is ten times higher and the efficiency is up to 99%. During the development process, designers need to build prototypes of various charging systems with components that can be put into production. If costs and time at this stage exceed budget, prototyping is likely to be a stumbling block. And Silver Dragon cleverly manufactured these gears used in the prototype mechanism of the charging connector through the 3D printing service of PTJ Shop.

Quickly Configurable Gears Online

With the online design tool in the PTJ Shop 3D printing service, engineers can design a gear in seconds. Designers simply select the gear module in the design tool and set the number of teeth and torque transmission to create a 3D model online for 3D printing of gears. As a result, hundreds of single and double gears can be created without using computer-aided design (CAD) software.

Wear-resistant Gears Can Be Delivered Shortly

These wear-resistant gears are 3D printed by industrial selective laser sintering (SLS) machines. Delivery-times are usually shorter. Li Guangxu, the founder of Silver Dragon, said: “In prototype manufacturing, a high degree of flexibility and fast delivery cycles are critical. Therefore, we chose to print multiple types of gears quickly with PTJ Shop’s online design tools.” The material used for 3D printing gear is PTJ Shop’s high-performance engineering plastic iglidurI6, which can withstand a temperature range of -40 ° C to + 80 ° C, can withstand pressures up to 44MPa, and has high wear resistance. In the igus test laboratory, engineers found it to be more robust than traditional plastic polyoxymethylene (POM). During the test, the gear was run at 12 revolutions per minute (RPM) and the applied torque was 5 Nm. The test results show that the gears made by 3D printing of iglidurI6 material still have normal performance and almost no wear after 1,000,000 cycles; while the machined gears made of POM material wear after 321,000 cycles It was damaged after 621,000 cycles.

Automotive Prototype Manufacturing

The Dongcheng electric vehicle charging system uses a highly wearable igus plastic gear that can be quickly designed to achieve more convenient parking and charging. (Source: PTJ Plastic Machining)

About PTJ Shop:

PTJ Shop is an internationally renowned manufacturer of engineering plastic sliding non-standard bearings and CNC processing plants. The company is headquartered in Dongguan, with operations in 35 countries and regions, and employs approximately 200 people worldwide.

Link to this article: Fast Prototype Example: 3D Printed PTJ Engineering Plastic Wear-resistant Gears

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:Fast Prototype Example: 3D Printed PTJ Engineering Plastic Wear-resistant Gears

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cnc Machining,Thank!^^