CNC lathes and turning centers are high-precision and high-efficiency automated machine tools. Equipped with a multi-station turret or power turret, the machine tool has a wide range of processing performance, which can process linear cylinders, oblique cylinders, arcs and various threads, grooves, worms and other complex workpieces, with linear interpolation, arcs Interpolate various compensation functions, and play a good economic effect in the mass production of complex parts.

“CNC” is the abbreviation of Computerized Numerical Control in English. The CNC machine tool automatically processes the processed parts according to the pre-programmed processing program. We put the part’s machining process route, process parameters, tool motion trajectory, displacement, cutting parameters (spindle revolutions, feed, back tooling, etc.) and auxiliary functions (tool change, spindle forward, reverse, etc.) Cutting fluid on, off, etc.), according to the instruction code and program format specified by the CNC machine tool, write a processing program list, and then record the content of the program list on the control medium (such as punched paper tape, magnetic tape, disk, magnetic bubble memory) ), and then input into the numerical control device of the numerical control machine tool to command the machine tool to process the parts.

This whole process from the analysis of the part drawing to the preparation of the control medium is called the compilation of the numerical control program. The difference between CNC machine tools and ordinary machine tools processing parts is that CNC machine tools automatically process parts according to the program, while ordinary machine tools must be operated by humans. We can achieve the purpose of processing different parts by changing the program that controls the motion of the machine tool. Therefore, CNC machine tools are particularly suitable for processing small batches of parts with complex shapes and high precision requirements.

Since the CNC machine tool must process the parts according to the program, after the programmer compiles the program, it is input into the CNC device to direct the work of the machine tool. The input of the program is through the control medium.

The Basic Composition Of CNC Lathe

Table of Contents

The CNC lathe is composed of CNC device, bed, headstock, tool post feed system, tailstock, hydraulic system, cooling system, lubrication system, chip conveyor and other parts.

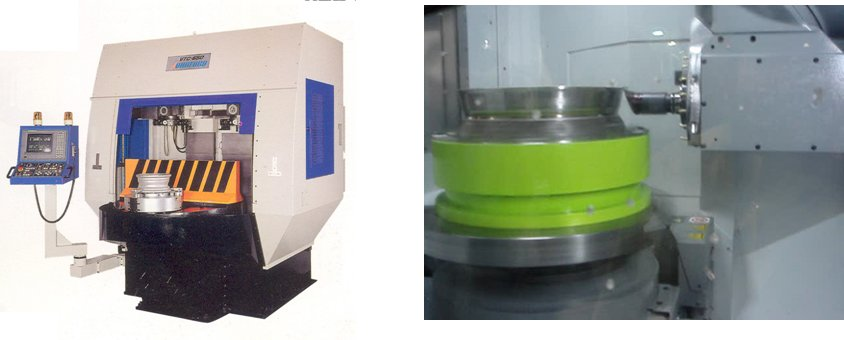

CNC lathes are divided into two types: vertical CNC lathes and horizontal CNC lathes.

Vertical CNC lathes are used for the turning of disk parts with larger turning diameters.

Horizontal CNC lathes are used for turning processing of parts with long axial dimensions or small disks.

Horizontal CNC lathes can be further divided into economical CNC lathes, ordinary CNC lathes and turning machining centers according to their functions.

- Economical CNC lathe: A simple CNC lathe formed by reforming the turning feed system of an ordinary lathe with a stepping motor and a single-chip computer. The cost is low, the degree of automation and functions are relatively poor, and the machining accuracy of turning is not high. It is suitable for turning machining of rotary parts with low requirements.

- Ordinary CNC lathe: a CNC lathe that is specially designed in structure according to the requirements of turning processing and is equipped with a general CNC system. The numerical control system has strong functions, high degree of automation and processing accuracy, and is suitable for turning processing of general rotary parts. This CNC lathe can control two coordinate axes at the same time, namely the x-axis and the z-axis.

- Turning machining center: On the basis of ordinary CNC lathes, a C-axis and power head are added. More advanced machine tools also have a tool magazine, which can control the three coordinate axes of X, Z and C. The linkage control axis can be (X, Z), (X, C) or (Z, C). Due to the addition of the C-axis and milling power head, the processing functions of this CNC lathe are greatly enhanced. In addition to general turning, it can also perform radial and axial milling, surface milling, and holes and diameters whose centerline is not at the center of the part’s rotation. Drilling and other processing of holes.

Hydraulic chuck and hydraulic tailstock

Hydraulic chuck is an important accessory for clamping workpieces during CNC turning. Ordinary hydraulic chucks can be used for general rotary parts; special chucks are required for parts whose clamping parts are not cylindrical; use bar materials directly A spring chuck is required when machining parts. For parts with a large ratio of axial size to radial size, the CNC bearing lathe needs to use a live center mounted on a hydraulic tailstock to support the end of the part to ensure the correct processing of the part. The tailstock has ordinary hydraulic tailstock and programmable hydraulic tailstock.

Tool holder of CNC lathe

CNC lathes can be equipped with two tool holders:

- The special tool holder is developed by the lathe manufacturer itself, and the tool holder used is also special. The advantage of this tool holder is low manufacturing cost, but lacks versatility.

- General tool holder. According to certain general standards (such as VDI, German Association of Engineers) and produced tool holders, CNC lathe manufacturers can choose and configure according to the functional requirements of CNC lathes.

Milling Power Head

After the milling power head is installed on the tool post of the CNC lathe, the processing capacity of the CNC lathe can be greatly expanded. Such as: using a milling power head for axial drilling and milling of axial grooves.

Tools for CNC lathes

When turning parts on a CNC lathe or turning machining center, the position of the tool on the tool holder should be reasonably and scientifically arranged according to the tool holder structure of the lathe and the number of tools that can be installed, and attention should be paid to avoid the tool when the tool is stationary and working. Interference phenomenon with the machine tool, the tool and the workpiece, and the tool.

Link to this article:Cnc Turning

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cnc Machining,Thank!^^