Re-grinding refers to materials that have been processed at least once, and then the gate, waste, etc. are ground or shredded. Please note that even the most “primitive resins” may have one or more processing histories, because they are compounded and pelletized during manufacturing. The original resins may have additional processing histories because of additives (such as color). , Fillers, stabilizers, lubricants, etc.) require a second mixing step. This “mixing” can be carried out by the resin supplier or in a separate mixing plant.

As a result of these processing histories, polymers may experience degradation in physical, chemical, and flow properties. The first problem to check if there is any doubt about the quality of the resin is the decrease in polymer chain length or molecular weight. This is done through the melt flow rate (MFR) test. If the chain is broken, the MFR of the pure resin will increase. Glass fiber-filled polymers are a special case because glass fibers break during processing and special rules apply.

Can I mix my REGRIND?

Table of Contents

The cause of molecular weight degradation is important, but it is not the main topic of this article. Is the mixture acceptable? If you shred the chain (for example, by processing a wet material that you think is dry), you will encounter trouble (hydrolysis), and this material should not be mixed with the original material. Although most processors say they can tell whether the resin is wetted by the melt or the appearance of the part, unfortunately, they are wrong. The hydrolysis reaction consumes water, and the parts look and perform well at room temperature.

Maintaining polymer chain length is only the beginning. Pollution may be the single biggest problem with recycled materials. It will be contaminated by other resins, colors, dirt, fine powder, metals, etc. Some plants contain a lot of recycled materials. They know that these recycled materials are contaminated and cannot be used, but they still keep them in the books under the name of “valuable”. Recycled materials sit there, taking up valuable inventory space.

Other resin/regrinding complications may be the loss or consumption of additives, such as release agents, antioxidants, acid scavengers, and antistatic agents, as well as previous thermal history, as well as color decline, fiber length reduction, excessive drying, etc.

What levels can be used?

There is one last point, we need to discuss the level of use of recycled materials. How much is allowed and what is actually used? In medical applications, the typical answer is no. The industry range is 0 to 100%. In addition, the target level can be a number, while the actual level used is usually a very different number. Just because you are using the most advanced weighing mix does not guarantee that you are at the target regrind level. What is your strategy to ensure the target level of recycled materials?

To develop strategies and optimize the value of recycled materials, it is important to understand the complications involved. Proper workshop procedures and discipline must be adopted to avoid disasters. The list of complications is important, and each has subtle differences:

• Track and record the actual regrind level in the part.

• Degradation of polymers in recycled materials.

• Wide range of particle size in recycled materials. Should you re-granulate? For any injection molding screw, it is extremely difficult to uniformly melt various particle sizes or shapes.

• Contamination of other plastics, colorant carriers, metal, wood, dust, cardboard, etc. The system can be mashed without spending a lot of money, and after mixing at any percentage, it will never leave the system unless you sell all of the recycled material.

• Excessive fines in the regrind. Fines are known to cause black or white spots.

• Differences in processing due to the above problems. These will be random and it will be difficult for the processor to capture and adapt.

If you want to mix recycled materials with virgin materials, you must deal with all these issues. They may be processed on paper, but it is almost impossible to control them in the production workshop. For example, how do you test to confirm that recycled materials are good and have not been contaminated or degraded? It can be done, but I haven’t seen its real realization yet. Then there are costs.

Bottom line: If recycled materials are good, then why mix them? If the recycled resin is not good, why should it be mixed? When you mix recycled materials with virgins, you will face various problems: there is no way to deal with pollution; there is also the problem of process stability, because various percentages of recycled materials will pass through your printing press.

alternative method

Therefore, do not mix recycled materials with virgin materials and encounter all the above-mentioned problems. Instead, use 100% recycled materials for evaluation. Store recycled materials until all the original resin is consumed. After the fines are removed, the feed is ground at a ratio of 100%. The advantages of this method are:

• Don’t worry about the amount of regrind or whether

Mix correctly.

• If the polymer degrades, the machine will tell you if you are using speed control and observe the actual pressure during transmission. Broken polymer chains will show a lower pressure when transported, because the speed control can maintain the same filling time.

• The particle size range may still be an issue, but it can be corrected by process adjustments.

• The possibility of contamination still exists, but this strategy is self-purifying; contamination will never mix with high-quality materials. In addition, you can now implement some strategies, such as using only virgin on the hot runner to prevent clogging of the soldering iron tip, and regrind only for cold runner applications.

• Excessive fines are still a potential problem, but you can add a dust collector.

• Tracking recycled materials becomes simple. The parts are marked with the resin batch number and the number of passes of the recycled materials used. If parts made of recycled materials are of poor quality or contaminated, they can be easily identified by the door number, removed from inventory and discarded. The possibility of contaminating the original resin is very low.

• The worst case can be tested. The parts are made from the original material, and then another batch of parts is made after five regrinds. Test their properties and compare them. If all properties are good, it can only be used three times at most to provide a safety margin.

For example, if you want to process a batch of 1000 pounds of waste at a waste rate of 1000%, you will generate 200 pounds of waste in the first process. In the second pass, you will make 160 pounds of high-quality parts and 40 pounds of scrap; in the third pass, you will get 32 pounds of parts and 8 pounds of scrap. If contamination occurs, only the contaminated channel is thrown away instead of the entire production process. Sell the last 8 pounds of scrap.

• Lower capital costs because you do not need to purchase mixing equipment.

• Regarding physical properties, Sue Janicki et al. completed a study. The data provided by “Material Cascade: An Alternative Recycling Form” proposed by SPE ANTEC in 1992 showed that its physical properties were well preserved after 5 times of 100% regeneration treatment.

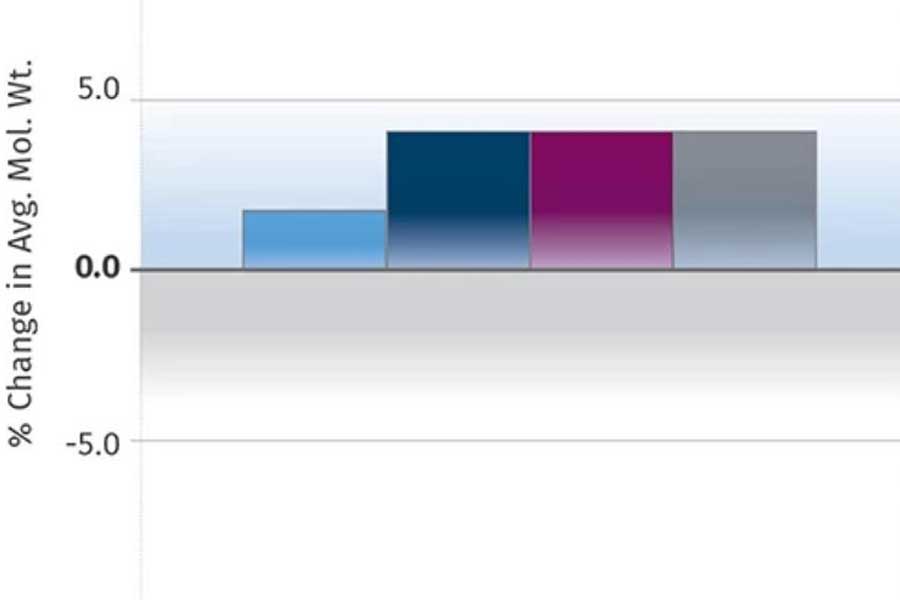

The attached tables and graphs provide some property retention data for the study. Table on page p. Figure 38 shows the excellent property retention in HIPS after the fifth backhaul pass. Figure on p. Figure 39 shows the significant increase in molecular weight (MW) of HIPS, fire-resistant PS (IRPS) and polycarbonate (PC).

However, the increase in MW is not true because the data is only for average molecular weight. The data shows that through processing, low molecular weight fractions are volatilized and removed, so the average molecular weight rises. (Interesting fact: removing these low molecular weight fractions actually improves the flame resistance of PC.)

Of course, there are some problems with using 100% recycled materials. Certain resins or colors may have processing problems, especially resins with glass fibers. It is known that processing glass-filled resin reduces fiber length, which reduces physical properties.

You may have to perform UL testing on 100% recycled parts.

Link to this article: These variables in injection molding must be strictly controlled or rework costs are high

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:These variables in injection molding must be strictly controlled or rework costs are high

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cnc Machining,Thank!^^