PEEK is very advantageous in 3D printed materials

Table of Contents

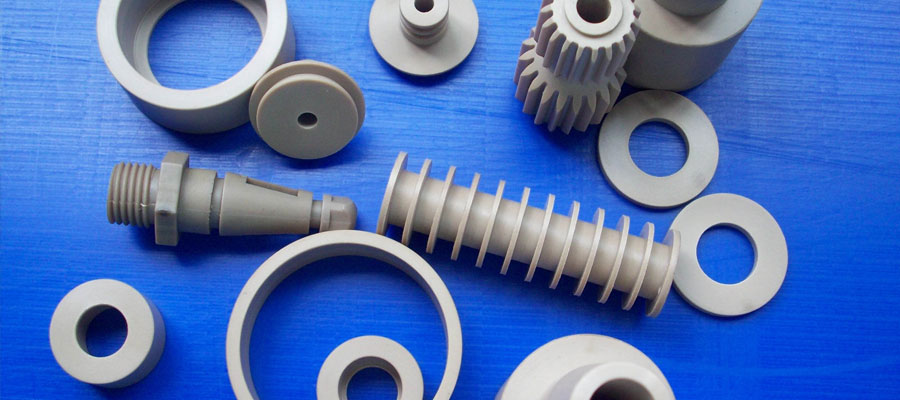

| PEKK material, the scientific name polyetheretherketone, was discovered by a US material company in the 1980s. It is a semi-crystalline, high-purity organic thermoplastic polymer with excellent strength, chemical resistance, low temperature and high temperature, and radiation resistance. These properties make it a highly promising material for a variety of 3D printing technologies and are used in many industries. |

Since PEKK materials have the above excellent characteristics, they have been developed into aerospace, automotive, biomedical, electronic and electrical industries.

Since PEKK materials have the above excellent characteristics, they have been developed into aerospace, automotive, biomedical, electronic and electrical industries.

Application of PEEK materials in the aerospace industry.

PEEK materials retain their outstanding material properties even when exposed to high temperatures and corrosive fuels. As a result, parts made from PEEK materials are widely used in the aerospace industry – external parts are resistant to rain and water; internal use reduces the risk of fire, and has excellent flame retardancy and low smoke and non-toxic properties. In addition, the overall weight and fuel cost can be reduced. A foreign supplier has manufactured parts with unique geometries through 3D printing of PEKK materials, providing low-weight, high-performance 3D printing components for aerospace, energy, medical and semiconductor applications.

The application of PEEK materials in the automotive field.

The fatigue resistance and chemical resistance of PEEK materials make them useful in automotive fuel management systems, and its lightness and strength make it possible to replace metal or aluminum alloy components in transmission, brake and air conditioning systems… Lowering the weight of the car and reducing noise is also the material of choice for custom-made auto parts for 3D printing&cnc machining china – for automotive parts that have been discontinued, 3D printing with PEEK material saves 90% of the cost of the original part.

The application of PEEK materials in the medical field.

In the medical field, PEEK offers economical and innovative components with excellent wear resistance, heat resistance, electrical resistance and chemical resistance. Its applications in the medical field mainly include dental instruments, endoscopes, dialyzers, etc., mainly for orthopedics. For example, in dental medicine, PEEK is used to replace a metal handle on a dental syringe or a sterile box for a root canal. PEEK is suitable for this because it can withstand up to 3000 autoclave sterilization cycles and maintain excellent mechanical strength and hydrolytic stability in hot water, steam, solvents or chemicals…

In addition to the application of high-precision applications such as military and artificial bones, PEEK’s excellent insulation will undoubtedly make it the darling of the electrical and electronic field. With excellent thermal performance, PEEK polymer parts can withstand traditional insulators. The high temperature that it withstands. And because of the pursuit of thinner, lighter, and smarter mobile devices, PEEK materials are also useful in mobile devices. In addition, there are some non-stick pans that can be seen in our daily life, such as PEEK materials that are non-toxic, high temperature resistant, non-hydrophilic, and wear resistant; and fan components in air conditioners, PEEK materials are printed in 3D. The fan can greatly improve the performance per unit weight, so that it has a better aerodynamic structure; there are pump valves that use the corrosion resistance of PEEK materials, etc…

At present, the application of PEEK has great potential. If the application range of PEEK material is to be expanded, it can be modified by blending, copolymerization modification, composite reinforcement modification, filling modification, nano modification and surface modification. Enhance the performance of certain aspects of PEEK materials.

Link to this article: The most promising 3D printing material – PEEK

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:The most promising 3D printing material - PEEK

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cnc Machining,Thank!^^